blog categories

recent posts

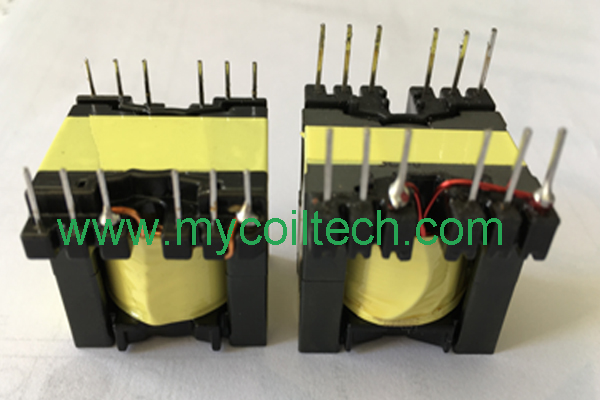

High frequency transformers for power supply

High-frequency transformers are the main components of switching power supplies. There are many topologies in switching power supplies. For example, a half-bridge power conversion circuit in which two switching transistors turn on to generate a high-frequency pulse wave of 100 kHz, and then transforms through a high-frequency transformer to output an alternating current. The number of turns of each winding coil of a high-frequency transformer is determined. The output voltage. The most prominent of the typical half-bridge transformer circuits are three high-frequency transformers: main transformers, drive transformers and auxiliary transformers (standby transformers).

High frequency SMPS transformer design principle

High frequency switching mode power supply transformer design requirements include: use conditions, complete functions, improve efficiency, reduce costs.

The conditions of use include two aspects: reliability and electromagnetic compatibility. Reliability refers to the fact that the high-frequency power transformer can work normally until its service life under the specific conditions of use. Electromagnetic compatibility means that high-frequency power transformers do not produce electromagnetic interference to the outside world, but can withstand external electromagnetic interference. One of the main causes of electromagnetic interference in high-frequency transformers is the magnetostriction of the magnetic core, and electromagnetic interference caused by high-frequency transformers is also caused by the attraction between the magnetic core and the repulsion between the winding wires.

High frequency power transformers perform three functions: power transfer, voltage conversion, and isolation. The voltage applied to the primary winding generates a magnetic flux change in the core, causing the secondary winding to induce a voltage, so that the electrical power is transmitted from the primary side to the secondary side; the voltage conversion is accomplished by the turns ratio of the primary and secondary windings; insulation Isolation is accomplished by insulating the primary and secondary windings.

3. Increasing efficiency is a common requirement for power supplies and electronic equipment, and it is also a design requirement for high-frequency transformers. The general efficiency must be increased to more than 95%. High-frequency power transformer losses include core losses (core losses) and winding losses (copper losses), and the transformer's iron loss and copper losses vary with the operating frequency of the transformer.

4. Reducing costs is also a design requirement for high-frequency power transformers, sometimes even decisive.

As professional transformer manufacturer in China, we are skilled at designing and producing kinds of transformers, our engineers were experienced in designing high frequency transformers, high precision current transformers, switching power supply transformers, toroidal transformer and other transformers. We make kinds of private tooling for transformers or inductor, because we are in this field for many years, we have good relationship with material suppliers.

Any kinds you need, you can send to us for a check, we are glad to service for you.

Contact: sales@mycoiltech.com