Why would you need a gapped core

July 22,2019.

What is magnetic core? Why use it?

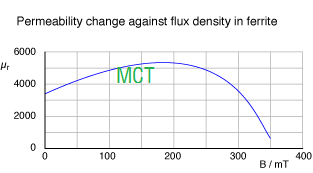

In wound components the magnetic core plays a vital role in raising the level of magnetic flux produced by a given current flow in the windings. That is to say, it increases the inductance. Unfortunately, our engineer find the increase in flux provided by ferromagnetic materials is never a simple linear factor, it also produced a lot of problems. At first, as the field strength is raised, the flux increase is a modest one. At higher currents the increase is more rapid, but at yet higher currents the flux increase slows again. Finally, saturation is reached and any further current increase generates but a minuscule increase in flux.

We use gapped core to alleviated following problems:

These changes in inductance with current are a nuisance at best. In high power transformers, however, saturation must be avoided at all costs because the ensuing drop in inductance leads to a sharp increase in magnetizing current, further core overload and a 'runaway' situation that often ends with smoke and flames.

Also, ferromagnetic materials all suffer from temperature dependance. In resonant circuits, for example, you normally prefer that the inductance remains constant with temperature and not detune the circuit as the environment changes.

In a high-Q tuned circuit you almost certainly want to run the core well below its saturation level - not through fear of flames but because you cannot afford to loose power to core hysteresis (which increases rapidly with B).

If you also encounter the above problems, we think the first step is to use gapped core and find whether it is working.

If you have any questions about the gapped core or experience, welcome to exchange and sharing with us.We are waiting your kindly information.