January 9,2020.

Do you want to measure the insulation resistance of a current transformer ? We have following ways to measure high precision current transformer insulation resistance, of course I hope you can give more advices.

I.Disconnect the power of the test part, remove or disconnect all external connections, and discharge the test part to ground. Tools such as insulating rods are required during discharge. Do not touch the discharge wires with your hands.

II.The primary winding of the current transformer is measured with a 2500V megger, and the secondary winding is measured with a 1000V megger. During the measurement, the measured winding is shorted to the megger, and the non-tested windings are shorted to ground.

III. Wipe off the dirt on the outer insulation surface of the test part with a dry and clean soft cloth, and wash it with a suitable cleaner if necessary.

IV. The terminal "E" on the megger is connected to the ground terminal of the test object, "L" is connected to the high voltage terminal, and "G" is connected to the shield terminal. Use shielded wires and insulated shield rods for connection. Stabilize the megger horizontally. When the speed of the megger is still rotating at a low speed, use a wire to short-circuit the "L" and "E" terminals momentarily, and the pointer should point to zero. When the circuit is open, the speed of the megger reaches the rated speed, and its pointer should refer to "∞". Then stop the megger, connect the ground terminal of the megger to the ground wire of the test object, connect the high-voltage end of the megger to the shielded connection line, and suspend the other end of the connection line (without the test product), When driving a megger or turning on the power, there should be no obvious difference in the indication of the megger. Then stop the megger and connect the shielded connection line to the measurement site of the test object.

V. Drive the megger to express the rated speed, or switch on the megohm meter power supply. After the pointer is stable (or 60s), read the insulation resistance value.

VI. After reading the insulation resistance, first disconnect the connection line connected to the high-voltage side of the test object, and then stop the megger.

VII. After disconnecting the megohmmeter, short-circuit the test object and discharge it to ground.

VIII. The temperature, humidity, meteorological condition, test date and instrument used of the equipment under test shall be recorded during the measurement.

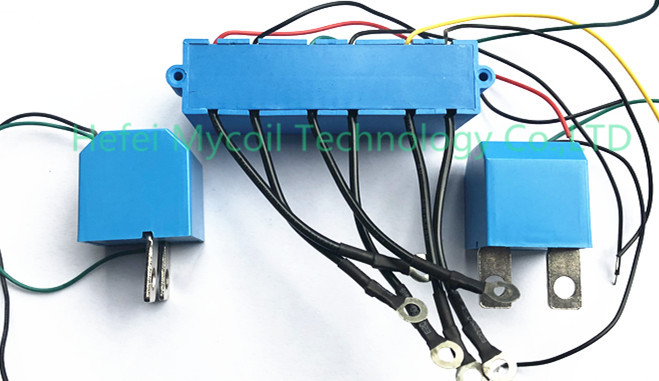

We produce and design various current transformers and voltage transformers. Such as miniature current and voltage transformers; electric meter current transformers; CT transformer for coils; switching power supply current transformers.

These current transformers are widely used in electronic watt-hour meters, power transmitters, power measurement, relay protection, instrumentation, industrial control and other fields. We use full-automatic loop winding machines and high-precision testing instruments to make the products produced with high precision, good linearity, small size, light weight, and strong anti-interference ability.