ET20 Series High Frequency Inductor Coil Former

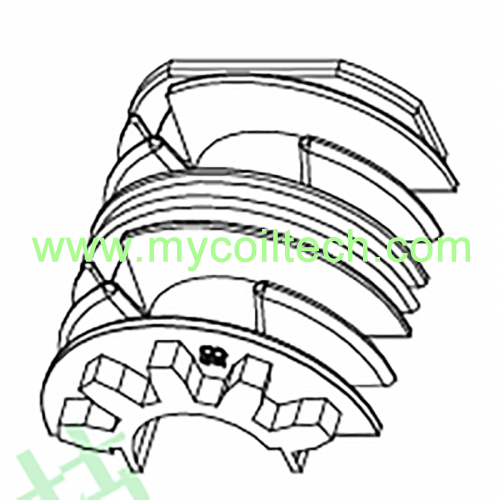

ETD 20 Common mode choke,This product uses PBT material as the preferred material for the inductor Bobbin, which can enhance the performance of the inductor in multiple dimensions: it has excellent insulation performance, with a stable dielectric constant and high breakdown voltage resistance, effectively isolating the coil from the core, avoiding the risk of leakage, and ensuring the electrical safety of the inductor in different voltage scenarios. It also features excellent high-temperature resistance, with a long-term operating temperature of 120-150℃ and a short-term temperature resistance exceeding 200℃. It can easily withstand the heat generated by copper and iron losses during the operation of inductors, preventing structural deformation to maintain stable performance. In addition, PBT material has excellent mechanical strength. Its high rigidity and impact resistance can firmly support the winding of the coil, making it less likely to be damaged during assembly and significantly enhancing the overall structural reliability and service life of the inductor. Moreover, it has excellent formability and fluidity, and can be precisely injection molded into complex-structured Bobbin, meeting the size and pin layout requirements for the miniaturization and integration of inductors. Coupled with its strong environmental resistance to moisture and chemical corrosion, it can ensure the continuous and stable operation of inductors under various humid, hot or harsh working conditions.

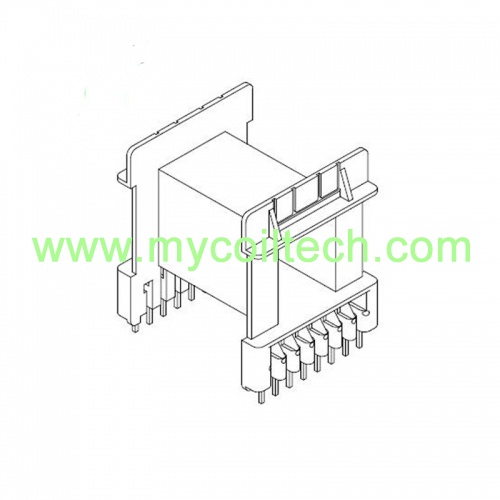

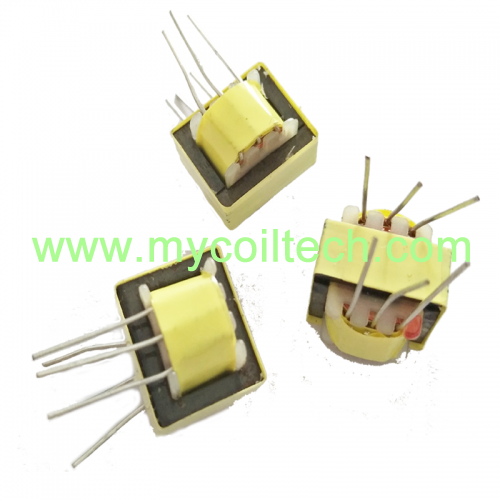

ET20 Multi Section Inductor Base2+2 pins ET20 horizontal inductor base, phenolic material base for ET20 filter. Base Size=21.0mmX21.0mmX11.6mm. Parallel Distance=18.5mm. Pin Distance=10.0mm. We manufacture final ET20 filter inductor, accept custom made transformers.

ET20 Multi Section Inductor Base2+2 pins ET20 horizontal inductor base, phenolic material base for ET20 filter. Base Size=21.0mmX21.0mmX11.6mm. Parallel Distance=18.5mm. Pin Distance=10.0mm. We manufacture final ET20 filter inductor, accept custom made transformers. Filter Inductor ET20 Coil FormerET20 choke coil bobbin. PBT material ET20 coil former. Bobbin Size=15.6mmX12.3mm. Multi section bobbin, supply horizontal/vertical ET20 header plate/inductor base. We manufacture final ET20 filter inductor, accept custom made transformers.

Filter Inductor ET20 Coil FormerET20 choke coil bobbin. PBT material ET20 coil former. Bobbin Size=15.6mmX12.3mm. Multi section bobbin, supply horizontal/vertical ET20 header plate/inductor base. We manufacture final ET20 filter inductor, accept custom made transformers. ET20 Series High Frequency Inductor Coil FormerETD 20 Common mode choke,This product uses PBT material as the preferred material for the inductor Bobbin, which can enhance the performance of the inductor in multiple dimensions: it has excellent insulation performance, with a stable dielectric constant and high breakdown voltage resistance, effectively isolating the coil from the core, avoiding the risk of leakage, and ensuring the electrical safety of the inductor in different voltage scenarios. It also features excellent high-temperature resistance, with a long-term operating temperature of 120-150℃ and a short-term temperature resistance exceeding 200℃. It can easily withstand the heat generated by copper and iron losses during the operation of inductors, preventing structural deformation to maintain stable performance. In addition, PBT material has excellent mechanical strength. Its high rigidity and impact resistance can firmly support the winding of the coil, making it less likely to be damaged during assembly and significantly enhancing the overall structural reliability and service life of the inductor. Moreover, it has excellent formability and fluidity, and can be precisely injection molded into complex-structured Bobbin, meeting the size and pin layout requirements for the miniaturization and integration of inductors. Coupled with its strong environmental resistance to moisture and chemical corrosion, it can ensure the continuous and stable operation of inductors under various humid, hot or harsh working conditions.

ET20 Series High Frequency Inductor Coil FormerETD 20 Common mode choke,This product uses PBT material as the preferred material for the inductor Bobbin, which can enhance the performance of the inductor in multiple dimensions: it has excellent insulation performance, with a stable dielectric constant and high breakdown voltage resistance, effectively isolating the coil from the core, avoiding the risk of leakage, and ensuring the electrical safety of the inductor in different voltage scenarios. It also features excellent high-temperature resistance, with a long-term operating temperature of 120-150℃ and a short-term temperature resistance exceeding 200℃. It can easily withstand the heat generated by copper and iron losses during the operation of inductors, preventing structural deformation to maintain stable performance. In addition, PBT material has excellent mechanical strength. Its high rigidity and impact resistance can firmly support the winding of the coil, making it less likely to be damaged during assembly and significantly enhancing the overall structural reliability and service life of the inductor. Moreover, it has excellent formability and fluidity, and can be precisely injection molded into complex-structured Bobbin, meeting the size and pin layout requirements for the miniaturization and integration of inductors. Coupled with its strong environmental resistance to moisture and chemical corrosion, it can ensure the continuous and stable operation of inductors under various humid, hot or harsh working conditions. +86(0)55166196829

+86(0)55166196829 sales@mycoiltech.com

sales@mycoiltech.com Lily~Mycoiltech

Lily~Mycoiltech