blog categories

recent posts

blog tags

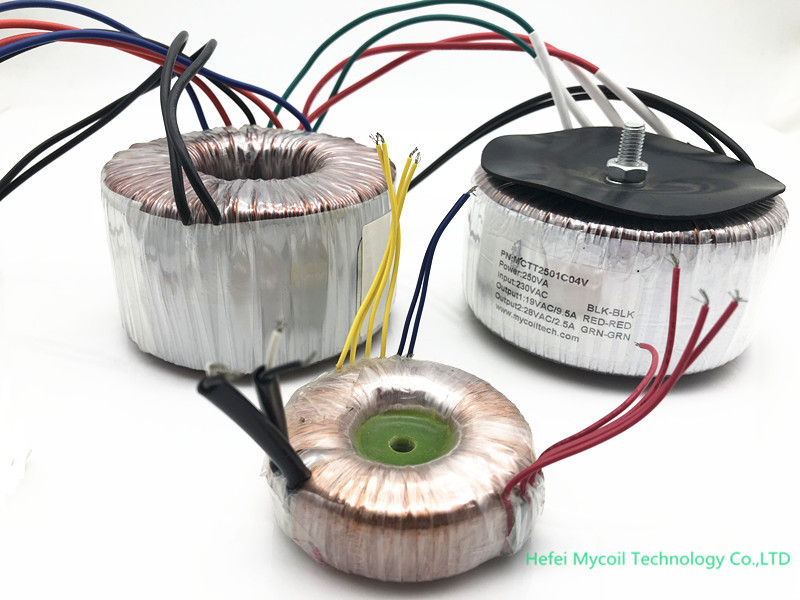

Toroidal transformer is a large type of electronic transformer, which is widely used in home appliances and other electronic equipment with high technical requirements. Its main use is as a power transformer and isolation transformer. Toroidal transformers have a complete series in foreign countries, which are widely used in computers, medical equipment, telecommunications, instruments, lighting, etc., and are mainly used in home appliances, audio equipment and automatic control equipment, and quartz lighting. Power toroidal transformer has excellent performance-price ratio, good output characteristics and anti-interference ability.

According to our production experience, today we will talk about the working principle of the toroidal transformer, the winding method, the installation method and so on.

I. Toroidal transformer working principle

The core of the toroidal transformer is made of high-quality cold-rolled silicon steel sheet (thickness generally below 0.35mm), which is seamlessly rolled, which makes its core performance better than the traditional laminated core. The coil of the toroidal transformer is evenly wound on the core, and the direction of the magnetic field lines generated by the coil is almost completely coincident with the core magnetic circuit. Compared with the laminated type, the excitation energy and core loss will be reduced by 25%.

Therefore the toroidal transformer has the following advantages:

1) High electrical efficiency

The stacking factor can be as high as 95%, the core magnetic permeability can be 1.5 ~ 1.8T (the laminated core can only take 1.2 ~ 1.4T), the electrical efficiency can be as high as 95% or more, and the no-load current is only 10% of the laminated type.

2) Small size and light weight

The toroidal transformer is half lighter than the laminated transformer. As long as the cross-sectional area of the core is kept equal, the toroidal transformer is easy to change the ratio of the length, width and height of the core, and it can be designed to meet the required dimensions.

3)Less magnetic interference

The core of the toroidal transformer has no air gap, and the windings are evenly wound on the toroidal core. This structure makes the magnetic leakage small and the electromagnetic radiation small. No additional shielding is required. Can be used in high-sensitivity electronic equipment, such as low-level amplifiers and medical equipment.

The vibration noise is small and the frequency response is wide, which can improve the sound quality of the power amplifier.

II. Toroidal transformer winding method

Wind the primary winding first, take a high-quality high-strength enameled wire with a diameter similar to the original wire, and double-wind on the "I" -shaped wire shuttle.

2) The double thread head is adhered to the outer circumference of the ring-shaped core with double-sided tape, and the thread shuttle is wound in the inner hole of the ring-shaped core. After one layer of coil is wound, apply a layer of insulating paint, cover it with cellophane, and then wind the second layer of coil.

3) After winding, connect the heads and tails of the two coils to make them in series. The other two wire ends are soldered out with a soft wire and insulated. A layer of interlayer insulation paper is added to the primary system and then the secondary winding is wound. The winding method is similar to that of the primary winding.

4) After all the windings have been wound, put the toroidal transformer in the incubator for a period of time to dry the insulation paint. Then wrap the outer layer with a thick layer of insulating paper, and the toroidal transformer is completed.

III. Toroidal transformer installation

Whether it is a broadcast power amplifier or a professional power supply transformer, the transformer is designed according to the parameters of the power amplifier. If low vibration, low noise and other performance requirements are required, the transformer can be cast with epoxy resin, and at the same time, it can be installed with a base or gland.

Sometimes the equipment has space and volume restrictions. In addition to limiting the size of the transformer as much as possible, you can also change its installation method. Using an L-shaped base, the toroidal transformer can be installed upright.

Some occasions, such as shielding, or special occasions such as rainproof and waterproof, will be equipped with a shell, and then fixed by a nut. Different special occasions will have different customization schemes. There are three main installation methods for toroidal transformers:

1) Pouring epoxy resin and fixing it with nuts in the middle.

2) Gland + rubber pad + rubber pad, fixed with nuts.

3) Gland + upper rubber pad + lower rubber pad + base, fixed with nuts

IV. What parameters are required for a customized toroidal transformer?

1) Industry: Because the requirements of each industry are different, engineers need to understand which industry the toroidal transformer is used to design in order to meet the needs of customers;

2) Output power: the wattage obtained by multiplying the output voltage by the output current;

3) Input voltage: Generally, it will be designed according to 220V, but can also be customized according to requirements if there are special requirements;

4) Output voltage and current: whether the toroidal transformer is single winding or multi-winding, what is the output voltage and output current of each winding;

5) Size: whether the diameter and height of the transformer are required;

6) Installation method: Install the bracket, middle hole potting, full potting, etc. as usual;

7) Other special requirements: such as lead length, whether the lead needs to be added with a terminal plug, etc.

Hefei Mycoil Technology Co.,LTD produce and design various toroidal transformers, high frequency transformers, inductors, current transformers, EMI filters. If you have any requests, welcome to contact us.

Email: sales003@mycoiltech.com

Skype: live:sales003_125

Contact: Miss Lily