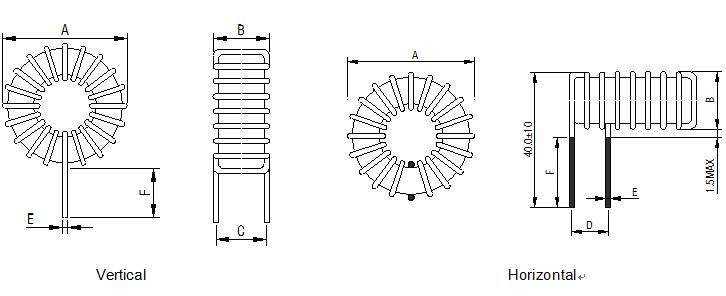

Powder core toroidal inductor. With high efficiency powder iron core. Vertical and horizontal orientations optimize EMI/RFI. Custom design available. Compatible with low cost through-hole assembly.

brand:

MCTitem no.:

MCT-Low EMI Toroidal Inductor Seriesshipping port:

ShanghaiFactory hot selling low EMI powder core inductor, fast delivery time and goos after-sale service, we can design to meet different applications, samples can be provided in 5 days. If you have any requests, welcome to contact us.

Quick Details

|

Part No: MCT-Low EMI Toroidal Inductor Series |

Brand name: MCT |

|

High saturation current up to 10A |

Custom made: Available |

|

High efficiency powder iron core |

Logo: Can be customized |

|

Operating temperature: -40°C to 105°C |

Pay terms: T/T |

|

Packing: Carton, can custom |

MOQ: Any quantity |

|

Lead time: 25 days after payment |

OEM: Available |

|

Type: Vertical, horizontal |

Shipping: Air, Ship, etc |

|

Lead time: 25 days after payment |

Certification: ISO9001,ROHS,CE |

Part Information

Product Name: Low EMI Toroidal Inductor for High power LED Ballasts

Products Range: Transformers, Inductors, coils, bobbins, ferrite cores.

Applications: High power switch-mode power supplies. Power line filters. High power audio filters. Solar inverter. White goods. Motor drivers.

Samples time: 7-10 days for customized parts, 3-5 days for standard parts.

Packing Details: PP packing belt + Outer packing hard paper carton + inner packing pearl cotton or plastic tray

Product Specification

|

MCT PN |

L(uH) |

Tolerance |

DCR(Ω)max |

IDC(A) |

DIMENSION:E |

|

MCT-01-200M |

20 |

±20% |

0.021 |

3.0 |

0.70 |

|

MCT-01-300M |

30 |

±20% |

0.035 |

2.0 |

0.60 |

|

MCT-01-600M |

60 |

±20% |

0.038 |

3.0 |

0.70 |

|

MCT-01-680M |

68 |

±20% |

0.101 |

1.0 |

0.45 |

|

MCT-01-101M |

100 |

±20% |

0.081 |

2.0 |

0.60 |

|

MCT-01-221M |

220 |

±20% |

0.190 |

1.0 |

0.45 |

|

MCT-02-220M |

22 |

±20% |

0.014 |

5.0 |

0.95 |

|

MCT-02-290M |

29 |

±20% |

0.020 |

4.0 |

0.85 |

|

MCT-02-350M |

35 |

±20% |

0.026 |

3.0 |

0.80 |

|

MCT-02-580M |

58 |

±20% |

0.061 |

2.0 |

0.60 |

|

MCT-02-900M |

90 |

±20% |

0.044 |

3.0 |

0.80 |

|

MCT-02-111M |

110 |

±20% |

0.069 |

2.0 |

0.65 |

|

MCT-02-131M |

130 |

±20% |

0.146 |

1.0 |

0.45 |

|

MCT-02-471M |

470 |

±20% |

0.286 |

1.0 |

0.45 |

|

MCT-03-250M |

25 |

±20% |

0.016 |

5.0 |

1.00 |

|

MCT-03-320M |

32 |

±20% |

0.021 |

4.0 |

0.90 |

|

MCT-03-430M |

43 |

±20% |

0.030 |

3.0 |

0.80 |

|

MCT-03-650M |

65 |

±20% |

0.055 |

2.0 |

0.65 |

|

MCT-03-111M |

110 |

±20% |

0.042 |

4.0 |

0.85 |

|

MCT-03-131M |

130 |

±20% |

0.055 |

3.0 |

0.80 |

|

MCT-03-151M |

150 |

±20% |

0.159 |

1.0 |

0.45 |

|

MCT-03-231M |

230 |

±20% |

0.108 |

2.0 |

0.65 |

|

MCT-04-500M |

50 |

±20% |

0.022 |

5.0 |

1.00 |

|

MCT-04-600M |

60 |

±20% |

0.030 |

4.0 |

0.90 |

|

MCT-04-750M |

75 |

±20% |

0.039 |

3.0 |

0.80 |

|

MCT-04-820M |

82 |

±20% |

0.042 |

3.0 |

0.80 |

|

MCT-04-101M |

100 |

±20% |

0.033 |

5.0 |

1.00 |

|

MCT-04-151M |

150 |

±20% |

0.042 |

5.0 |

1.00 |

|

MCT-04-221M |

220 |

±20% |

0.059 |

4.0 |

0.90 |

|

MCT-04-271M |

270 |

±20% |

0.081 |

3.0 |

0.80 |

|

MCT-04-321M |

320 |

±20% |

0.131 |

2.0 |

0.65 |

|

MCT-04-431M |

430 |

±20% |

0.150 |

2.0 |

0.64 |

|

MCT-04-961M |

960 |

±20% |

0.438 |

1.0 |

0.50 |

|

MCT PN |

L(uH) |

Tolerance |

DCR(Ω)max |

IDC(A) |

DIMENSION:E |

|

MCT-05-900M |

90 |

±20% |

0.034 |

5.0 |

1.00 |

|

MCT-05-900M |

140 |

±20% |

0.064 |

3.0 |

0.80 |

|

MCT-05-900M |

200 |

±20% |

0.114 |

2.0 |

0.65 |

|

MCT-05-900M |

320 |

±20% |

0.068 |

5.0 |

1.00 |

|

MCT-05-900M |

450 |

±20% |

0.174 |

2.0 |

0.65 |

|

MCT-05-900M |

470 |

±20% |

0.354 |

1.0 |

0.45 |

|

MCT-05-900M |

1800 |

±20% |

0.680 |

1.0 |

0.45 |

|

MCT-06-820M |

82 |

±20% |

0.033 |

5.0 |

1.00 |

|

MCT-06-101M |

100 |

±20% |

0.042 |

4.0 |

1.01 |

|

MCT-06-131M |

130 |

±20% |

0.061 |

3.0 |

0.85 |

|

MCT-06-221M |

220 |

±20% |

0.121 |

2.0 |

0.70 |

|

MCT-06-301M |

300 |

±20% |

0.064 |

5.0 |

1.00 |

|

MCT-06-391M |

390 |

±20% |

0.088 |

4.0 |

0.90 |

|

MCT-06-471M |

470 |

±20% |

0.342 |

1.0 |

0.50 |

|

MCT-06-501M |

500 |

±20% |

0.124 |

3.0 |

0.80 |

|

MCT-06-781M |

780 |

±20% |

0.225 |

2.0 |

0.70 |

|

MCT-06-132M |

1300 |

±20% |

0.585 |

1.0 |

0.50 |

|

MCT-07-300M |

30 |

±20% |

0.009 |

10.0 |

1.60 |

|

MCT-07-350M |

35 |

±20% |

0.010 |

10.0 |

1.60 |

|

MCT-07-560M |

56 |

±20% |

0.020 |

7.0 |

1.30 |

|

MCT-07-680M |

68 |

±20% |

0.021 |

7.0 |

1.30 |

|

MCT-07-820M |

82 |

±20% |

0.023 |

7.0 |

1.30 |

|

MCT-07-101M |

100 |

±20% |

0.036 |

5.0 |

1.00 |

|

MCT-07-151M |

150 |

±20% |

0.053 |

4.0 |

1.00 |

|

MCT-07-201M |

200 |

±20% |

0.078 |

3.0 |

0.85 |

|

MCT-07-301M |

300 |

±20% |

0.142 |

2.0 |

0.70 |

|

MCT-07-851M |

850 |

±20% |

0.211 |

2.0 |

0.70 |

|

MCT-08-750M |

75 |

±20% |

0.014 |

10.0 |

1.60 |

|

MCT-08-131M |

130 |

±20% |

0.031 |

7.0 |

1.30 |

|

MCT-08-201M |

200 |

±20% |

0.056 |

5.0 |

1.00 |

|

MCT-08-251M |

250 |

±20% |

0.027 |

10.0 |

1.60 |

|

MCT-08-471M |

470 |

±20% |

0.064 |

7.0 |

1.30 |

|

MCT-08-681M |

680 |

±20% |

0.105 |

5.0 |

1.00 |

MECHANICAL DIMENSIONS (ALL DIMENSIONS ARE IN mm)

|

Series |

A |

B |

C |

D |

F |

|

1 |

18.0 |

11.5 |

11.0 |

17.5 |

15.0 |

|

2 |

22.0 |

12.5 |

12.0 |

21.5 |

15.0 |

|

3 |

24.0 |

11.5 |

10.5 |

23.0 |

15.0 |

|

4 |

27.0 |

13.5 |

12.5 |

26.0 |

15.0 |

|

5 |

30.0 |

17.0 |

16. |

29.0 |

15.0 |

|

6 |

32.0 |

16.0 |

15.0 |

30.0 |

15.0 |

|

7 |

36.0 |

19.5 |

18.0 |

34.5 |

15.0 |

|

8 |

42.5 |

21.5 |

20.0 |

41.0 |

15.0 |

If you have any questions, please contact us or leaving your comments, we will give you fast reply.

Email: sales003@mycoiltech.com

Skype: sales003_125

Contact: Miss Lily Yu

TEL: +86 551 6619 6829

Toroidal Inductor Ferrite Core Power Inductor

Toroidal Inductor Ferrite Core Power Inductor

Sendust core/ferrite core toroidal inductor. "RoHS Compliance" product, label outside package. Vertical and horizontal orientations optimize EMI/RFI. Compatible with low cost through-hole assembly.

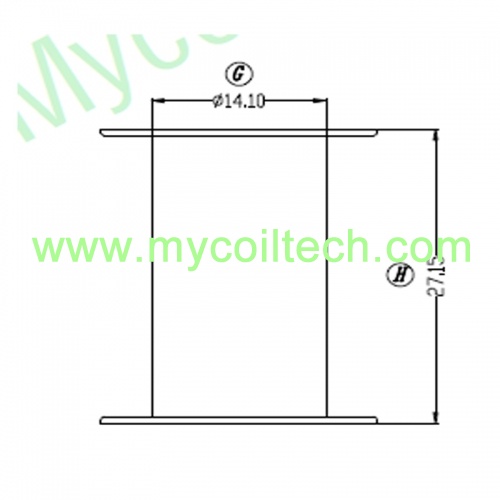

High Current Toroidal Choke Coil Base

High Current Toroidal Choke Coil Base

Common mode filter base. High stability and good quality custom choke coil base. We can provide samples for testing in 5 days. Special requirements can make tooling. PA66 material plastic base for inductor. UL REC:94V-0.

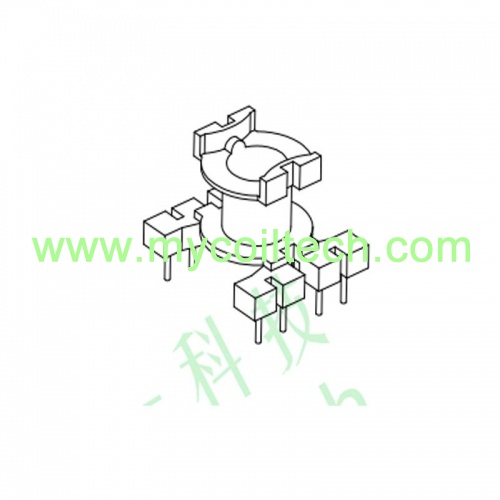

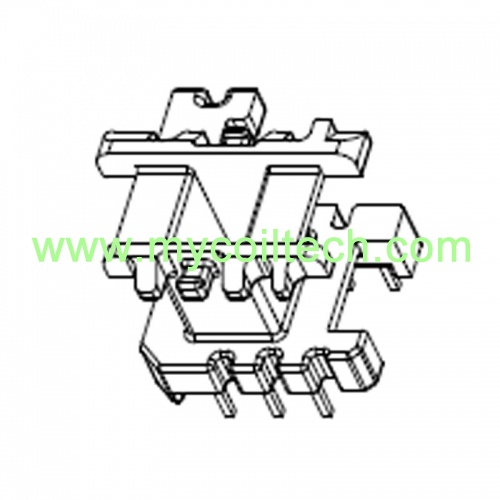

RM6 Control Transformer Vertical Bobbin Pin 4+4

RM6 Control Transformer Vertical Bobbin Pin 4+4

RM6 ferrite core bobbin for audio transformer. Vertical RM6 4+4 pin bobbin. Bobbin Size=18.7mmX17.1mmX12.7mm. Parallel Distance=15.3mm. Pin Pitch1=5.1mm. Pin Pitch2=3.7mm. RM6 transformer has strong anti-interference and attenuation of low transmission, mainly used for PCB circuits, mobiles, printers, computers and other equipments.

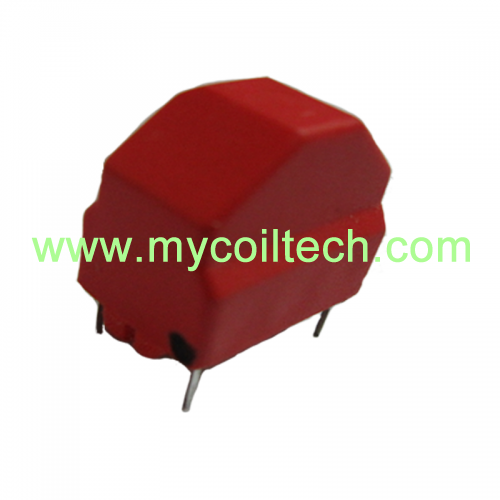

Vertical Encapsulated Common Mode Choke Coils with High Frequency

Vertical Encapsulated Common Mode Choke Coils with High Frequency

Vertical encapsulated common mode choke has small profile, large current, low resistance, high frequency and low loss, common mode filter and toroidal inductor.It is excellent EMI suppressor.

Vertical 3+4+2 Pins EI16 Transformer Bobbin Dip Bobbin

Vertical 3+4+2 Pins EI16 Transformer Bobbin Dip Bobbin

3+4+2 Pins Vertical Bobbin,Phenolic Material,UL REC:94V-0 Size=21.2mmX17mmX12mm